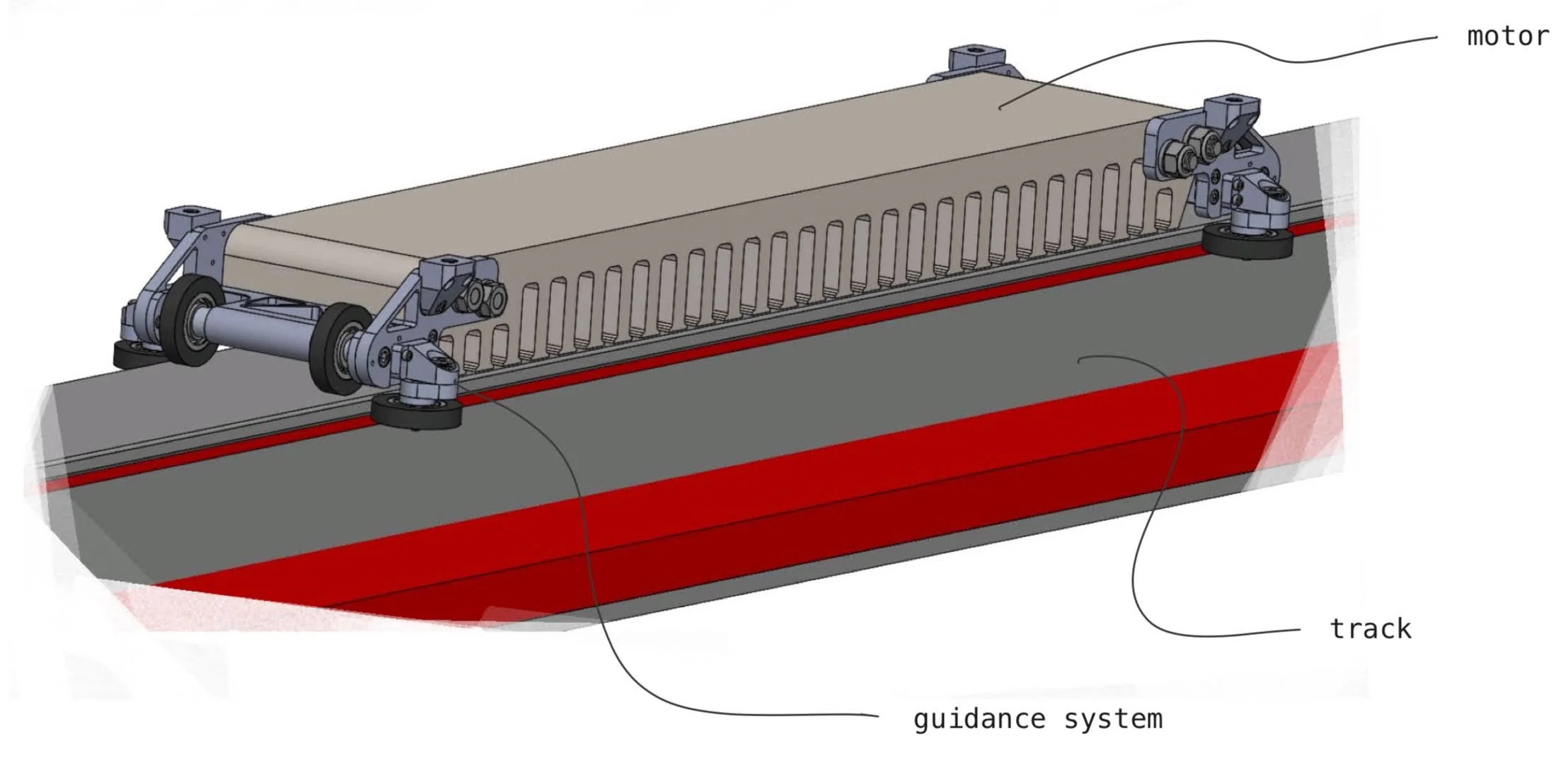

Linear Motor Guidance System

Waterloop is one of North America’s only student led design teams developing AC Induction motors completely from scratch.

To harness the power of these 30kW in-house designed motors, I was tasked with developing the mechanical systems that keep the motor on the track.

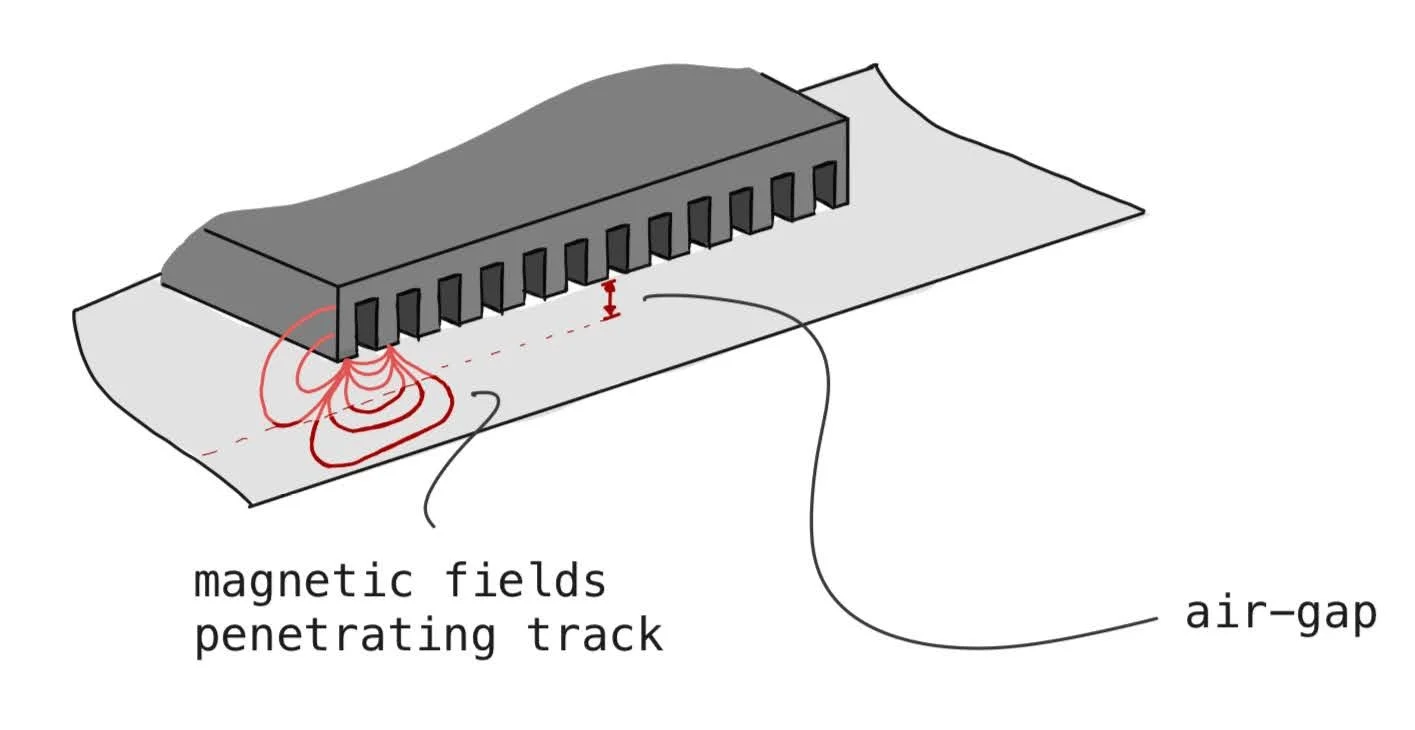

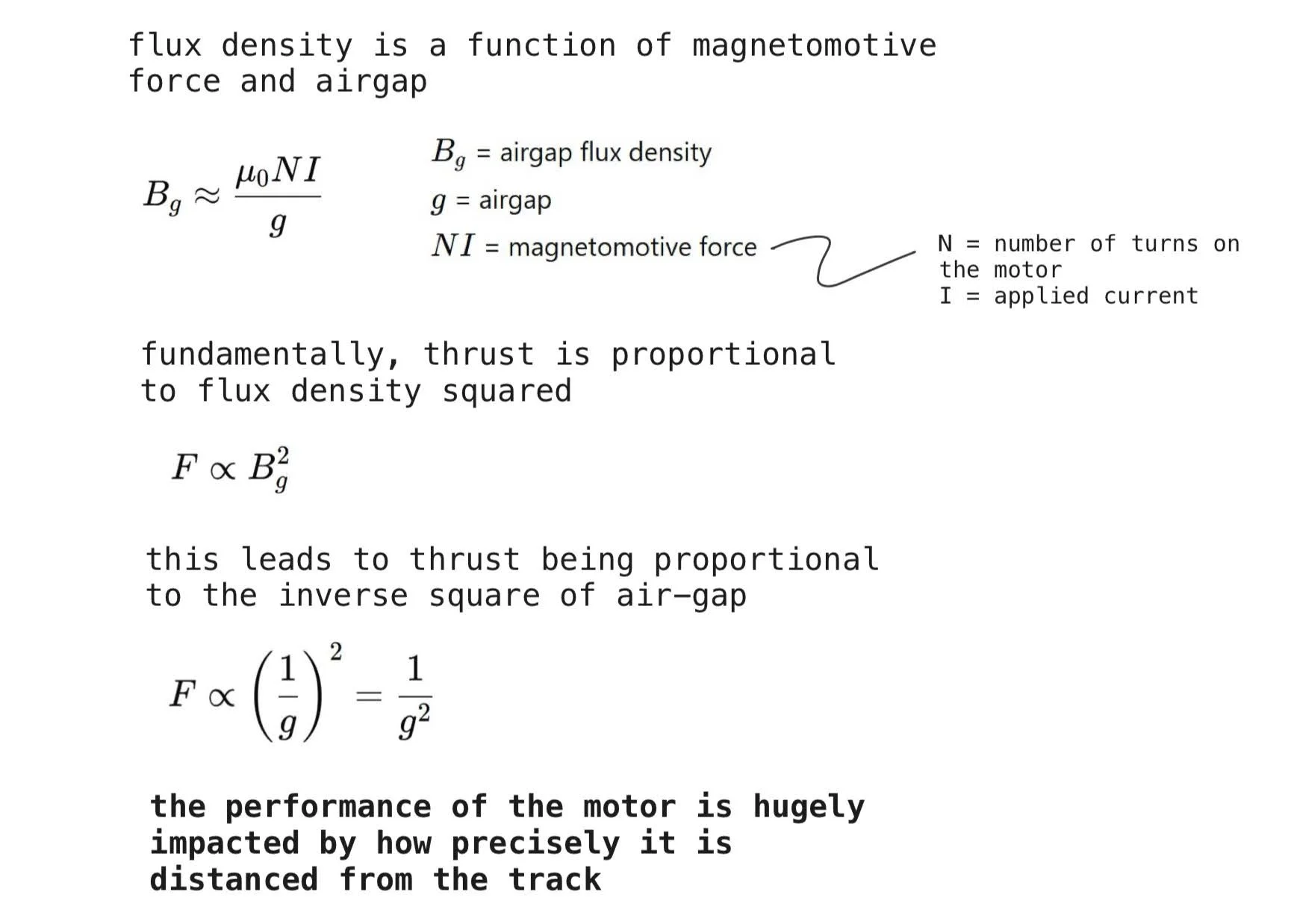

In this case, decreasing the airgap by even a fraction of a milimeter adds significant start-up thrust to the system allowing the pod to accelerate faster and hit a higher top speed.

Decreasing air-gap is a balancing act between being so close to the track that the motor scrapes and gets damaged, and being too far away that performance is being left on the table.

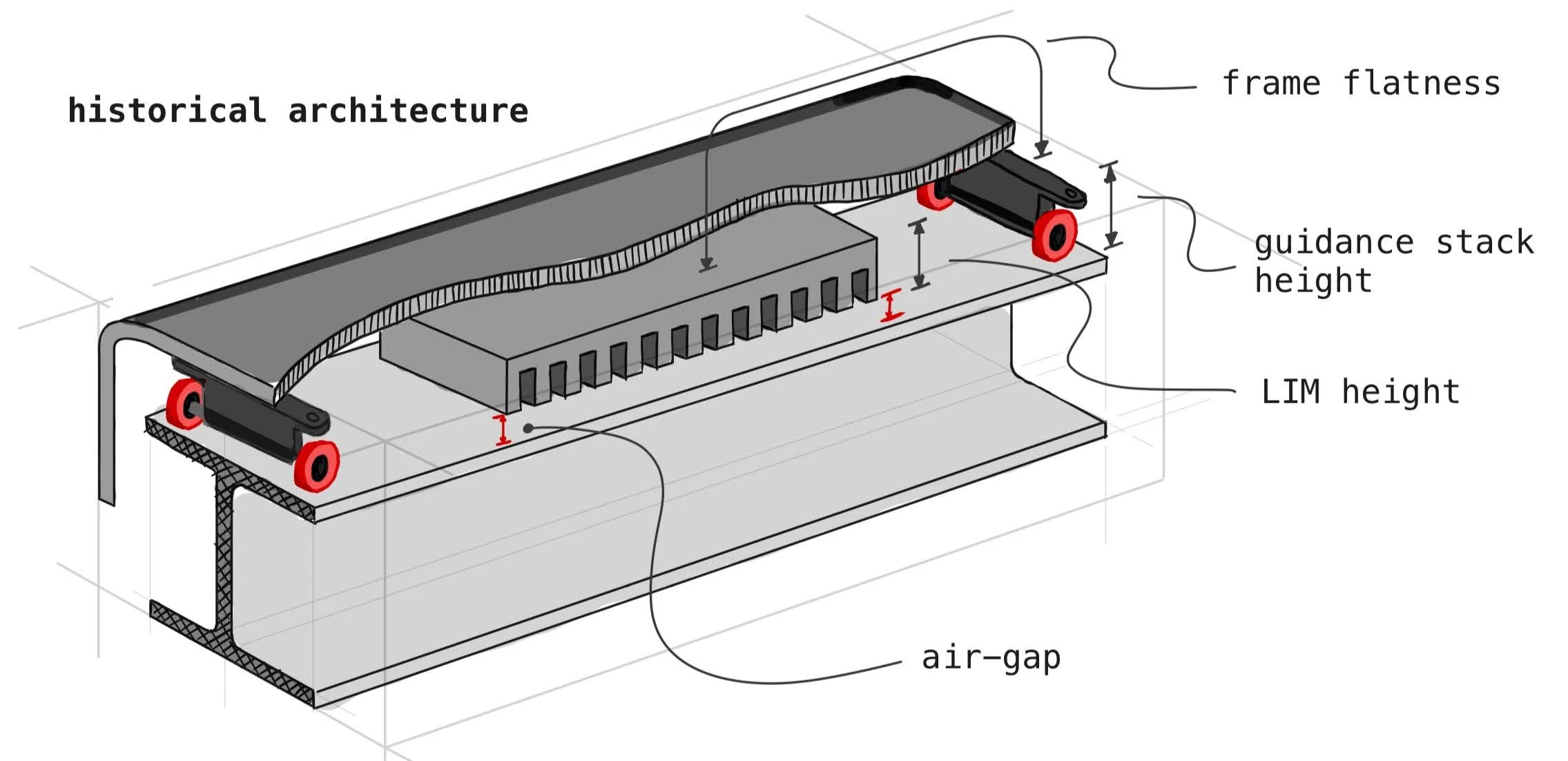

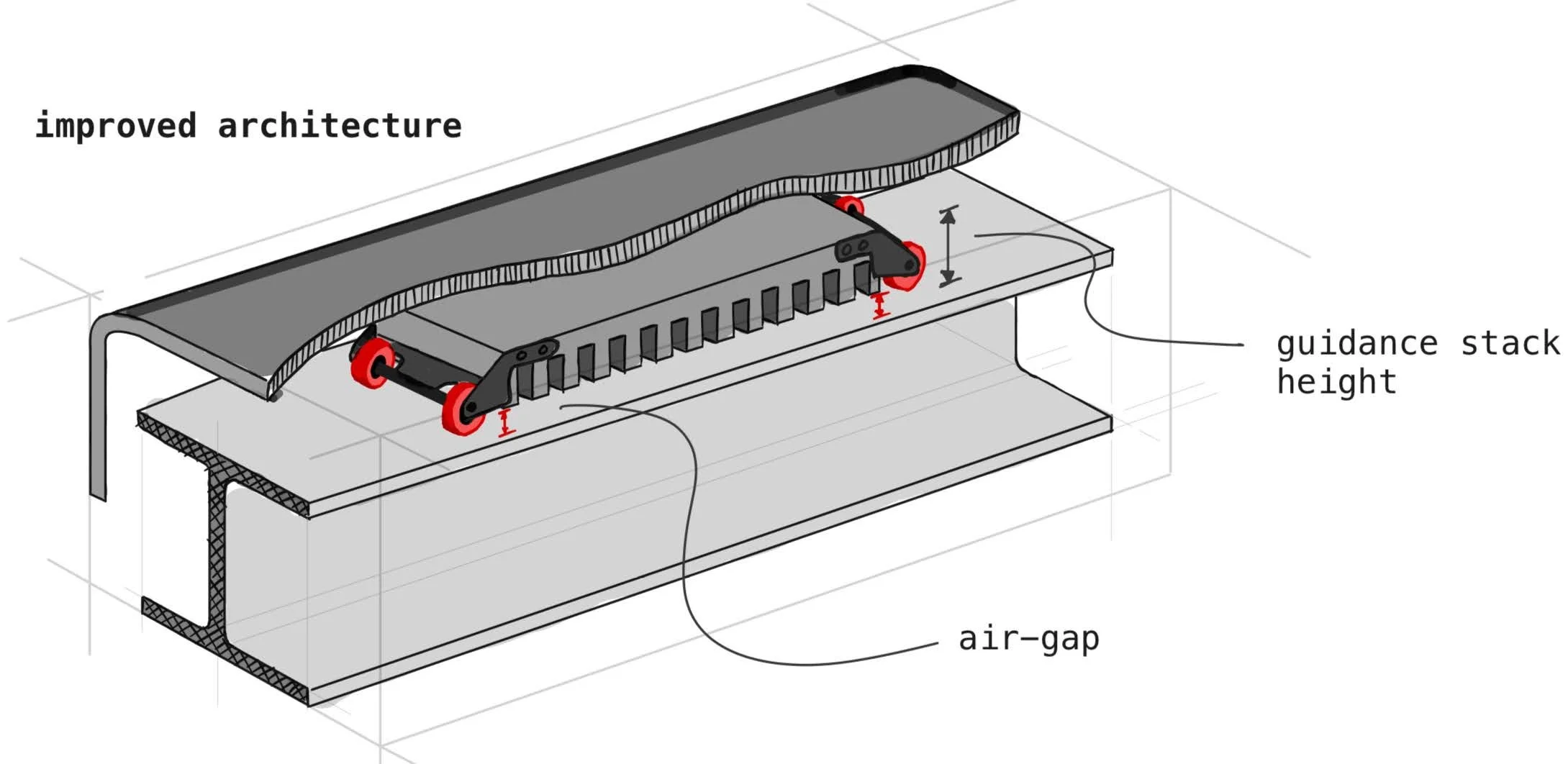

Previous guidance architectures separated the motor and guidance into two distinct sub-systems that are attached with a frame. My concept attached the guidance system directly to the motor allowing for a smaller stackup of parts, less airgap variation, and simpler adjustment.

With the general concept down, I mocked it up in CAD.

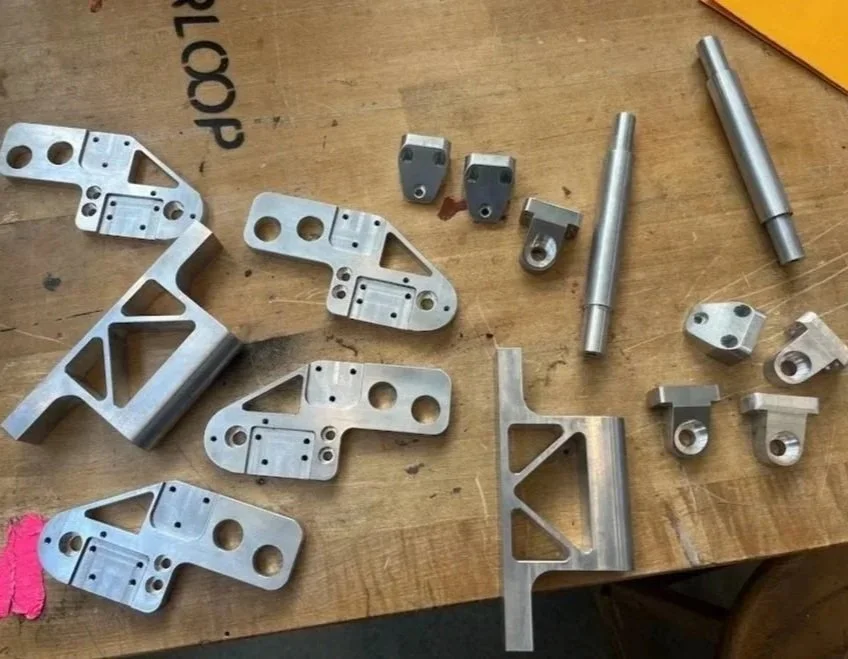

Some key considerations:

DFA - leaving sufficient clearance for fasteners

Locating Strategies - locating parts off machined features, not through fasteners

AG adjustability - the fastener holes to the motor are oversized to allow adjustment of airgap

Side adjustement - the side wheels are on cams that swing and adjust to control pressure on side of track. These cams are designed to self tighten.

Parts were designed to be easily machined by manual mill/lathe and a 3 axis CNC. I hand machined everything apart from the side bracket and middle spacer (pictured) (3 axis CNC).

I also made wheels with bearings and OTS urethane hollow stock.

In hindsight, I should have just bought off the shelf wheels. These were difficult to assemble and were not perfectly true.

Full guidance system assembled and fitted onto the motor.

I tested the system by making a mock motor out of wood and loading the system with 115lbs of weight (estimated weight of full system).

I measured the startup force and the continuous force using a force gauge.

Startup Force = 18N

Continuous Force = 12N

With roughly 600N of starting thrust generated by the motor, rolling resistance should not be a limitation.

This is the linear motor test with the full guidance system at 1.2% of the rated current.